One of the most interesting things about Rolex is the amount of time and energy the company puts into research and development – and moreover, R&D the fruits of which often never see the light of day, at least in the form in which they are originally patented. Fortunately for the curious, patents are a matter of public record, and if you're inclined, you can find fascinating examples in patent databases that give hints as to what the company spends its time researching, and even make some (at least semi-educated) guesses as to how information gleaned from basic research filters down to products that end up on consumer's wrists.

At Baselworld 2015, Rolex introduced a new movement in the newest version of the Day-Date: the caliber 3255. The Day-Date is one of the flagship models for Rolex, obviously, and it makes sense that they'd introduce a new flagship movement. The caliber 3255 is designed from the ground up for optimum performance in just about every respect imaginable, and though it follows the same basic ground plan that's been in place for mechanical watches since the debut of the lever escapement in 1755, based on what we heard about the movement when it was launched, it looks like just about every part of the movement has been scrutinized and most of them reworked – over 90%, according to Rolex.

Everything, including the Parachrom balance and newly reformulated lubricants, is in-house. Of course, the most significant upgrade is probably the Rolex Chronergy escapement, which uses a novel geometry, as well as a skeletonized (lighter, lower inertia) escape wheel to produce a 15% gain in efficiency in transmission of energy from the escape wheel, via the lever, to the balance itself. Since the lever and escape wheel are made of non-magnetic materials (nickel-phosphorus) and the balance spring is made from a non-magnetic niobium-zirconium alloy, the movement's highly resistant to magnetism as well.

All this adds up to an impression of a certain kind of research and development. You could look at it and characterize it as incremental, sure, but it's more than that; it's fundamental. These are improvements that haven't been made to create aura for a few months or to generate largely theoretical rather than practical advantages. They focus on things like better lubrication, superior power delivery from the mainspring through to the balance, and improved rate stability, in watches that are meant to be delivered not to a small group of connoisseurs, but to the general watch-buying public. So where do you get information on watchmaking fundamentals like variations in escapement geometry, and sliding friction in escapements, from?

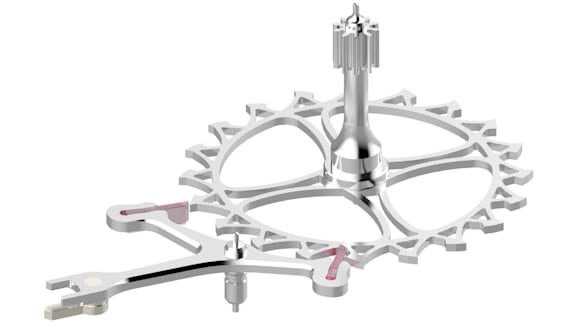

One place is from research into improved escapements. Probably the single most important improvement on the lever escapement in modern watchmaking was the Daniels co-axial escapement. It, as well as several other modern escapement designs (most notably in recent years, the Audemars Piguet direct-impulse escapement) represent attempts to combine the advantages of the chronometer escapement with those of the lever, without the disadvantages of either. The chronometer escapement is more efficient and needs no oil, but is delicate and prone to unlocking the escape wheel when it shouldn't, especially if jarred. The lever escapement, by contrast, offers great "safety" (security against accidental unlocking) but uses sliding friction to deliver energy through the lever, to the balance, which means you need to oil the escapement – and as oils break down, the rate of the watch becomes less stable. Rolex, rather unsurprisingly, has done research into developing an escapement with the same combination of safety, energy efficiency, and elimination of oil on impulse surfaces that characterizes the co-axial, and below are some images that show one such escapement, from online patent documents. The lever and escape wheel are shown; the balance isn't, but you can see the impulse roller (the center of the balance, which carries the jewel pushed by the escape wheel to keep the balance turning).

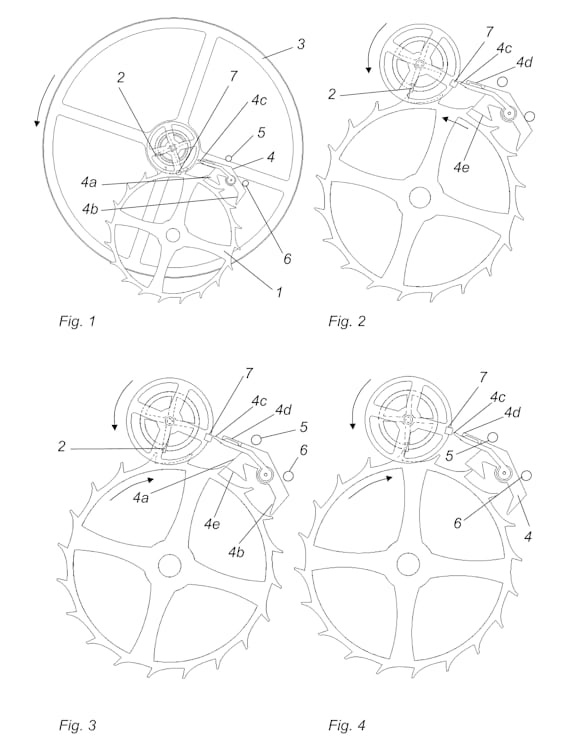

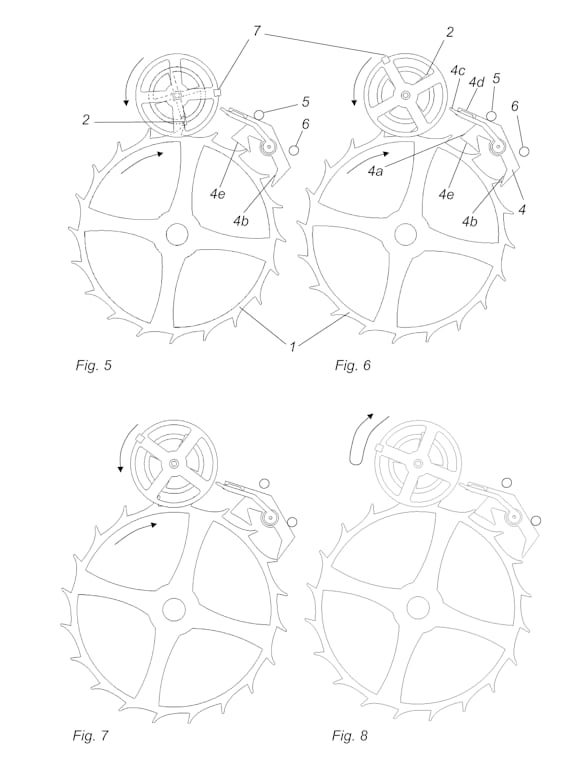

The action can be followed from top to bottom. In images Fig. 1-4 (above), the balance is turning counterclockwise and you can see the square detent jewel (7) on the "hub" of the balance (the impulse roller) lifting the detent rocker (4) to unlock the escape wheel. Fig. 4 is the moment when the escape wheel tooth hits the impulse jewel and pushes it. You'll notice that unlike the lever escapement, impulse is given directly (not through a lever) to the balance, so it's more efficient. The other thing you can see in Fig. 4 is that another escape wheel tooth is sliding along the lower surface of the detent rocker to push it towards the locking pin (5).

At Fig. 5, the lever is pushed home against the locking pin. At Fig. 6, another escape wheel tooth starts to slide against the detent rocker at 4b and this moves the lever back in the other direction, so that surface 4a locks the escape wheel.

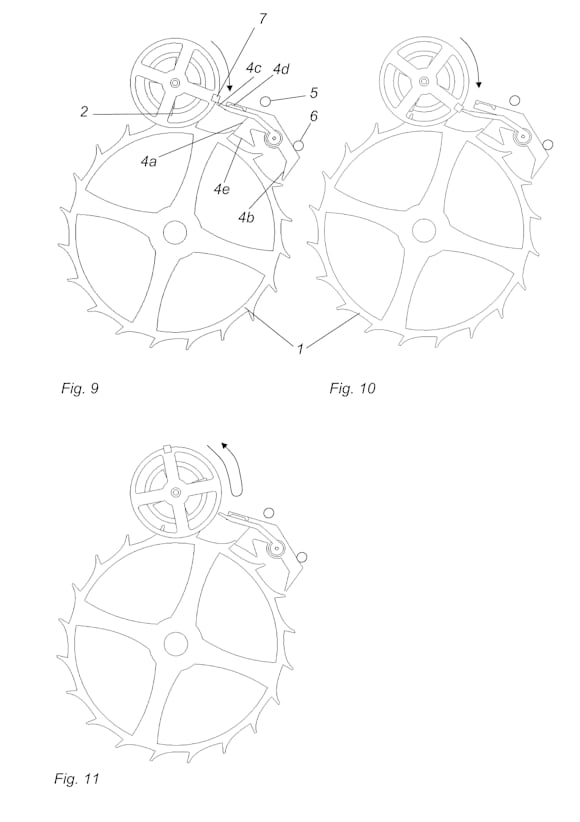

Fig. 9-10 show the detent jewel (7) passing the detent; note that the detent pivots on the rocker, and allows it to pass without unlocking the escape wheel.

The whole system works exactly like a chronometer detent escapement: you have direct impulse of the balance by the escape wheel, so there are no frictional energy losses. At the same time, the interaction of the escape wheel teeth with the lever provides good "safety" so that the lever is always exactly where it should be, and can't accidentally unlock the escape wheel. The whole thing is incredibly ingenious but it would be (as far as I can tell, and I'm an editor, not an engineer) a very demanding escapement to mass produce; the detent would be tiny; the sliding friction on the lever isn't problematic from a rate stability standpoint but might be from a wear standpoint (silicon/LIGA components might solve that problem) and so on. But the sheer cleverness of the design, as well as the extreme precision in the angles of interaction and geometry of the lever and escape wheel teeth, speak volumes to what the R&D staff at Rolex spend their days thinking about.

Naturally all that trickles down into production movements, as you can clearly see if you analyze the caliber 3255. Sure, the 40mm Day-Date is a drop-dead statement piece; the very definition of conspicuous consumption in some respects; the ur-luxury watch to generations of watch enthusiasts. Most of its buyers will never know and probably won't much care what's under the hood. But when you look at it, you can see a lot more: a watch that is, at least in terms of modern watchmaking fundamentals, one of the most technically advanced watches out there.

Our original Hands On with the 40 mm Day Date.

Our visit to all four Rolex Manufacturing Facilities.

Read the original patent here.

Read what Rolex has to say about the caliber 3255 right here.

No comments:

Post a Comment